Pressure Calibration

Express Dock pressure calibrators are important instruments used on vessels for accurate measurement and calibration of pressure systems. These devices are used to ensure that pressure-sensitive marine equipment, and systems onboard the ship are functioning correctly and within specified limits. Some of the instruments and electronics found on vessels that can be measured and calibrated with the help of pressure calibration equipment are pressure gauges, transmitters and switches. The accuracy and reliability of these pressure devices is thus maintained, further assuring the safe and efficient operation of various other express dock systems.

Types of pressure calibrators

Express Dock pressure calibrators are available in a wide range of measurement capabilities, typically covering pressures from a few millibars to several hundred bars. The specific range depends on the model and type of calibrator being used.

There are several types of pressure calibrators commonly used on vessels:

- Handheld Pressure Calibrators: These portable calibrators are compact and easy to use. They usually feature a built-in pressure source and a display for pressure readings. Handheld calibrators are suitable for on-site calibration and troubleshooting tasks.

- Portable Pressure Calibrators: Similar to handheld calibrators, portable pressure calibrators are designed for portability but offer additional functionality and higher accuracy. They may have advanced features such as data logging, multiple pressure ranges, and compatibility with various pressure units.

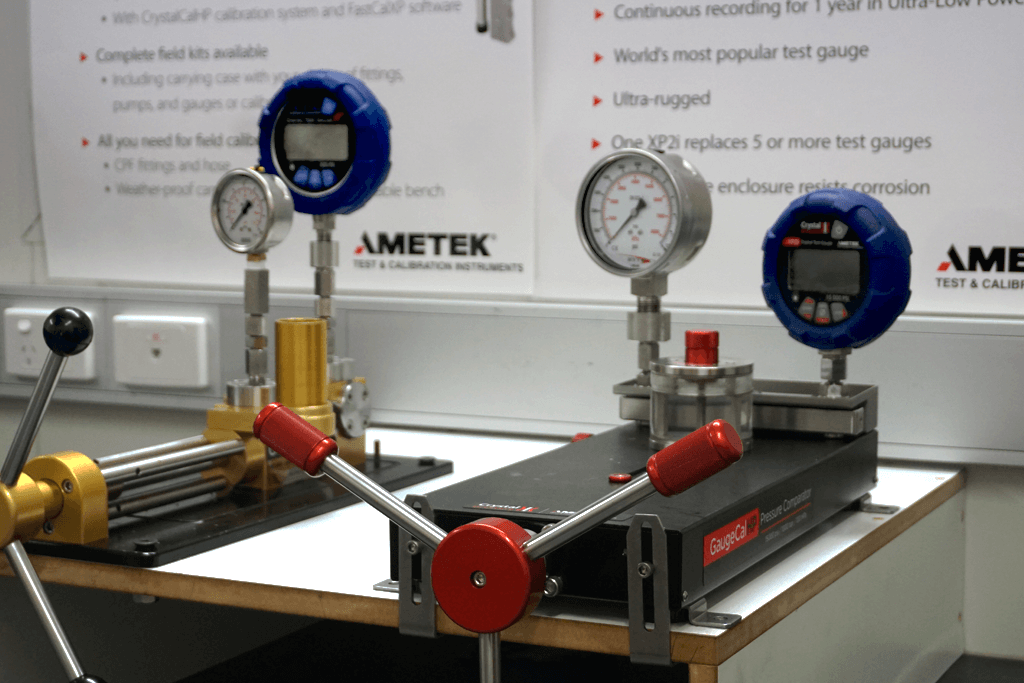

- Bench-Top Pressure Calibrators: These calibrators are larger, more sophisticated instruments that are typically used in dedicated calibration labs or workshops. They provide highly accurate measurements and offer a wide range of features such as automated pressure generation, multiple channels, and advanced calibration procedures.

Moreover, express dock pressure calibrators may include the following features:

- Pressure Generation: Pressure calibrators are equipped with a pressure source, which can be pneumatic (using compressed air or gas) or hydraulic (using a fluid). This allows them to generate precise pressures for calibration purposes.

- Pressure Measurement: They have a built-in pressure sensor or a connection port to connect an external pressure sensor. This enables the calibrator to measure and display the pressure accurately.

- Data Logging: Certain devices, especially digital pressure calibrators, have the ability to log pressure measurements at regular intervals. This feature is useful for documenting calibration procedures and generating reports.

- Communication Interfaces: Many modern pressure calibrators offer communication options such as USB, Bluetooth, or Ethernet, allowing them to connect to computers or other devices for data transfer and control.

- Multiple Pressure Units: Pressure calibrators can typically display pressure readings in various units, including bar, psi (pounds per square inch), kPa (kilopascal), MPa (megapascal), and more.

Express Dock Instruments & Controls helps you with the calibration procedure

Besides providing you with the pressure calibrator itself, our highly proficient technicians can assist you with the calibration procedure required for the electronic apparatus of your vessel. This process consists of using the pressure calibrator to apply a standard reference pressure to the instrument under test. The calibrator’s display is compared to the reading on the device being calibrated and adjustments are made if necessary. Consequently, the instrument is ensured to accurately measure the pressure.

Precise pressure measurements are vital for the safe and efficient operation of marine systems and instruments. Regular calibration of pressure instruments such as pressure gauges (gauge calibration is a critical process that ensures the accuracy of pressure measurements) helps identify any deviations or inaccuracies in their readings, allowing for corrective action to be taken. Calibrating pressure devices guarantees that critical systems such as fuel, hydraulic and pneumatic operate within the required specifications, reducing the risk of accidents or failures.

Express dock vessels, depending on their type and flag state regulations, often require regular calibration and certification of pressure instruments. Mr. Marine Instruments & Controls helps you at every step of this process, facilitating it and rendering your vessels safe and compliant. Additionally, our technicians undergo extensive training to handle pressure calibration equipment from all brands, including renowned manufacturers like Fluke (who provides digital pressure calibrators that comply with the UKAS standards – United Kingdom Accreditation Service), Wika, Additel, IKM Instrutek, Ametek, and Crystal Pressure.

Our offer of pressure calibrators

To provide our clients with ease of use and accessibility, our offer consists of hand-held pressure calibrators, such as the Wika Hydraulic High-Pressure Calibrator and the Wika Pressure Calibrator. Nonetheless, our specialists are trained to work on any type of pressure calibration equipment, including digital vacuum and pressure pumps, differential pressure gauges, transmitters, pneumatic devices and deadweight testers, and on any brand of pressure gauge calibration equipment, for instance popular manufacturers like Fluke, Wika, Additel, IKM Instrutek, Ametek or Crystal Pressure.

About Express Dock Instruments & Controls

Our technicians are available around the clock, operating in over 150 ports worldwide, to guarantee the safety and compliance of your vessel. To conveniently schedule your next service, please reach out to our team.

Furthermore, you can connect with us on well-known social media platforms like LinkedIn, Instagram and Facebook. Feel free to browse our website, give us a call, or send us an email to request a quote for your vessels.