Tank Level Monitoring

One of the services of utmost importance for your vessel offered by express dock Instruments & Controls is tank level monitoring. Tank level monitoring or tank level gauging refers to the measurement of liquids stored in large tanks in order to determine the volume of the product.

In the maritime industry, the applications of this measurement procedure are predominantly for assessing the liquid level in:

- ballast tanks

- cargo tanks(used for carrying liquid such as oil, chemicals or liquefied gasses)

- fuel tanks, e.g. heavy fuel oil tanks (H.F.O), marine diesel oil tanks(MOD) and express gas oil tanks (MGO)

- freshwater tanks

Each type of tank demands a specific level gauging system tailored to its purpose. Our skilled technicians are trained to work with most of the different types of tank gauging systems used in the maritime field, as well as the most popular makers which include Kingspan (e.g. the Watchman line), Honeywell, Panasia, MMC, Valcom.

why use tank gauging systems?

Tank level monitors are crucial for any operating vessel due to its various benefits. Using them favorably in the marine field ensures safe operations, efficient cargo management, protection of the environment and of the vessel and compliance with rules and regulations. Furthermore, the conveyed information can be used for an optimal planning of refueling activities or maintaining vessel stability. In consequence, their reliability and accuracy made tank monitoring systems a requirement for modern vessels.

Furthermore, the effective monitoring of tank levels is important for ensuring smooth operations, preventing spills and maintaining safety standards. Whether it’s a fuel tank, oil vat, or water storage tank, accurate monitoring of tank contents is essential. To achieve this, various technologies such as level sensors, temperature gauges, and remote access systems are employed. Worthy of mentioning, level sensors play a vital role in tank level monitoring, enabling real-time data collection and analysis. These sensors are designed to detect and measure the level of substances in a tank, including oil, water, and other liquids. By utilizing different measurement principles such as ultrasonic, pressure, or capacitive sensing, level sensors provide accurate readings of the tank’s contents. These sensors are available in a wide range of designs and configurations to suit various tank types and applications.

Express Dock Instruments & Controls will ensure the level gauging system on your vessel is running seamlessly and with excellent precision, all while respecting the official regulations.

What are the types of tank gauging systems?

Several technologies are employed for tank level gauging in the marine sector. These include:

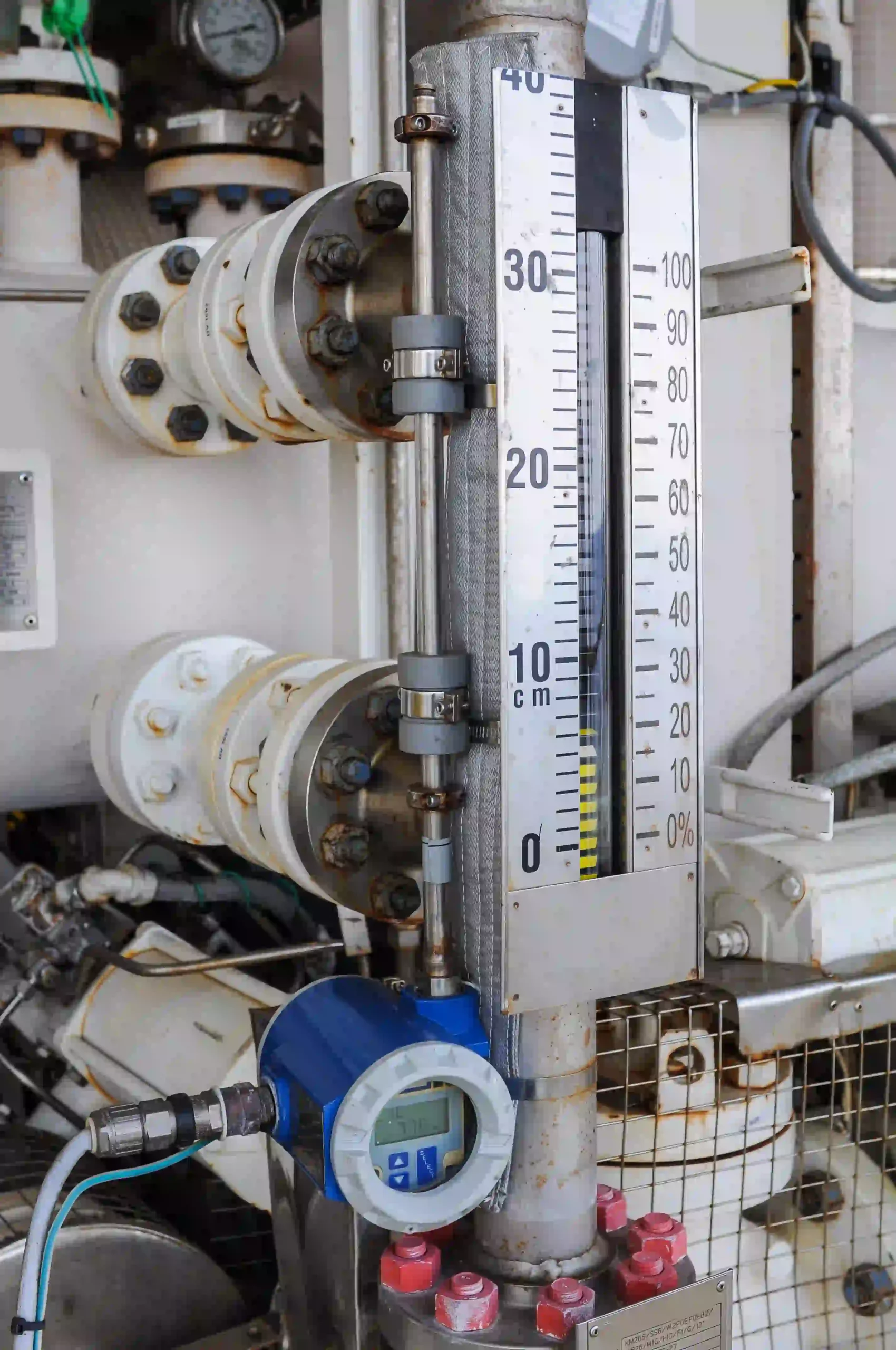

- Float Gauges: Float-based systems use a float that rises or falls with the liquid level, providing a visual indication or electronic signal.

- Pressure Transmitters: These systems use pressure sensors to measure the hydrostatic pressure at the bottom of the tank, which is proportional to the liquid level.

- Radar Gauges: Radar-based systems utilize microwave radar signals to determine the liquid level by measuring the time it takes for the signal to bounce back from the liquid surface.

- Ultrasonic Gauges: Ultrasonic sensors transmit sound waves that bounce off the liquid surface and are received back to calculate the level.

- Capacitance Gauges: Capacitance-based systems measure the change in capacitance between two electrodes as the liquid level changes.

Tank level monitoring services offered by Express Dock

Installation

Express Dock team of highly trained technicians will help with selecting the appropriate type of level gauging equipment, based on the specific needs of your vessel, such as the types of tanks used and other cargo requirements. Further factors that our experts will take into consideration are the type of measurement technology, compatibility with the already existing systems onboard of your vessel and compliance with the maritime regulations.

Calibration

Calibration is one of the most important steps to guarantee your tank level measurements will be accurately and optimally executed. Our experienced technicians will tend to the whole calibration process with the ultimate goal of providing precise readings corresponding to known liquid levels. This objective will be achieved by

configuring the system parameters, adjusting the sensor calibration settings and validating the accuracy of the measurements against a reference standard. Additionally, Mr. Marine Instruments & Controls is able to skillfully calibrate any brand of tank level gauging systems, including popular manufacturers like Kingspan (e.g. the Watchman line), Honeywell, Panasia, MMC, Valcom.